MaxCell® MaxWrap® reduced the total pulling tension and protected the cable during installation.

When Global InterXchange, LLC (GIX), a provider of dark fiber infrastructure solutions headquartered in Red Bank, New Jersey, began planning a high-capacity dark fiber network to connect the business-critical train tunnels between Lower Manhattan and Northern New Jersey, they understood there would be several challenges. Successfully completing a project of this scope would require extensive coordination and planning around permits, operations and logistics, but GIX knew they had the leadership to be successful. They were aware that it would take partnerships, engineering expertise, and an abundance of collaboration to build this new backbone route capable of meeting the growing connectivity and diverse needs of technology and businesses to service global customers.

The “PATH” to Connectivity

GIX's plan was to take new fiber optic cabling under the Hudson River via the Port Authority Trans-Hudson Corporation (PATH) commuter transportation system. The team would initially need to sit down with representatives from the Port Authority of New York and New Jersey plus the PATH team to strategize on the project.

With the growing digital transformation and the need for sustainable infrastructure, there are many benefits of utilizing diverse underground tunnels to support modernization of critical infrastructure.

This endeavor would be the first dark fiber network cross-Hudson tunnel installation in decades and would be a significant upgrade from the nearly twenty-year-old fiber infrastructure that was currently being utilized. Over the lifetime of the fiber cables, availability, performance, diversity and increase of capacity are required to ensure seamless data transport for all customers. Telecom, financial institutes, hyperscale’s, colocation facilities and other enterprises need high-speed bandwidth to operate a high performance and cost-efficient network. GIX’s state-of-the-art optical data transport equipment and today’s high-capacity fiber cabling would give global providers the diversity and low-latency connectivity that would deliver the performance their customers required.

Phase 1 of the GIX backbone route connects 60 Hudson NYC terminating at 5 suites with 2 POE to 165 Halsey New Jersey MMR. The network is located at a diverse southernmost Hudson crossing in the Port Authority PATH tunnel between New York and New Jersey.

Fast Forward

Data centers, data-driven enterprises and hyperscales require reliable, secure, diverse and low latency networks that can meet the growing and exploding demands for more bandwidth. Diverse dark fiber is a vital component that is required for today’s needs and the requirement for future-proof solutions to support enhanced connectivity and reduce network costs.

What are the Benefits of Dark Fiber?

For businesses that depend on high-speed, high-capacity performance and strategic control, a dark fiber network allows companies to create and control their own private network rather than leasing lite services. Dark fiber is layer one and provides a low-latency connectivity to support seamless data transmission. Some of the other benefits of a dark fiber network include:

- Diversity

- Scalability

- Increased security

- Reliability

- Performance

- Long-term cost savings

A Network Built on Collaboration

As mentioned, it takes collaboration and partnerships to succeed with a project like this. One such partner that helped GIX with this endeavor was MaxCell®. With a robust portfolio of network construction products, MaxCell® offers customers a flexible fabric innerduct that meets today’s construction needs and future proofs for expansion. With various options depending on project needs, MaxCell’s newest product MaxWrap® was the best solution for this project.

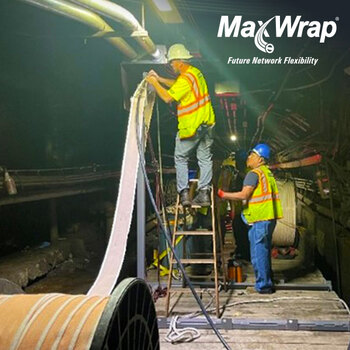

The completion of the fiber installation phase of the project would require pulling fiber optic cable across 1.4 miles of the PATH Tunnel under the Hudson River. These cables would connect into the zero maintenance manholes in both Lower Manhattan and Jersey City. Although fiber optic cable is extremely strong, the pull tension for this type of project can result in damage if not done correctly. The team from MaxCell® suggested utilizing the MaxWrap® fabric mesh solution that is strategically engineered to reduce cable load under tension during installation. This product is applied to the cable as it is pulled into the conduit, and it protects the installed cable in greenfield applications plus existing cable overlay applications.

Logistically, pulling fiber through tunnels is a difficult process and can result in a variety of challenges, such as obtaining cooperation from the Port Authority, coordinating with the construction company and vendors, scheduling equipment and material deliveries, not to mention, being able to communicate throughout the pull with no cell phone service underground and the limitations of two-way radios.

The fiber installation through the PATH Tunnel was done over a holiday weekend to minimize commuter delays. The MaxCell® team was onsite to work with GIX and Hylan to ensure that the process went smoothly, and obstacles could be solved quickly. HYLAN, a nationally recognized leader in turnkey infrastructure solutions, delivered seamless execution for this complex project.

“The support from the MaxCell® team was incredible. We didn’t want splices, mid span fiber pulls, and knew we had to maintain the fiber cable tension specification. A pull of this length was a milestone, and using MaxWrap® helped us monitor the process and make it a monumental success.”

- George Cornachini, Chief Technology Officer, GIX

Leveraging its extensive expertise in fiber optic builds and installations, HYLAN ensured the project was completed with precision and efficiency. MaxWrap® performed well in protecting the cable and reducing the total pulling tension during installation which consisted of an approximate 7,500-ft. continuous pull.

This portion of the project connecting Lower Manhattan to Northern New Jersey represents the first phase of a multi-phase project in GIX’s plan to build a massive connectivity ring that will serve the NY metro area and will include plans for a western route into New Jersey.

Benefits of MaxWrap®

- Reduces pulling tension during install

- Solves conduit span challenges

- Pulls further than traditional applications

- Cut and abrasion resistant

- Chemical and petroleum resistant

- Manufactured in the U.S.A.

- Includes engineering and onsite support

VIEW PRODUCTS