Deploying MaxCell Plenum in Tunnels Expands Capacity and Saves Money

Problem:

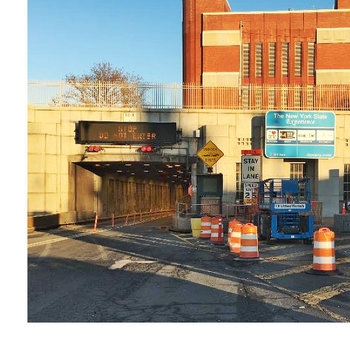

The Brooklyn Battery Tunnel is 1.727 miles in length and is the longest continuous underwater vehicular tunnel in North America. In 2013, Hurricane Sandy inundated the tunnel with salt water and destroyed much of the sensitive control and monitoring systems that existed within the tunnel. As part of the restoration project, new fiber optic cabling had to be installed in the tunnel.

Solution:

Nearly every bridge or tunnel poses unique pathway restraints such as limited conduit space, limited space to maneuver equipment, and exposure to elements causes expansion and contraction of rigid HDPE conduit and microduct. Using MaxCell Plenum, a flexible fabric innerduct solution, was a perfect fit for a long pull installation on the Brooklyn Battery Tunnel. Its unique fabric construction allows MaxCell solutions to conform to the shape of cables placed within, greatly reducing the wasted space associated with rigid innerduct.

Working with a local area electrical contractor, the MaxCell team faced the challenge of deploying new infrastructure within the constraints of the tunnel as well as minimizing investment costs. The number of conduits on this project was predetermined and by using MaxCell it meant the enduser was left with empty conduit for future system requirements.

There was over 8,700’+ in combined pull length on this project and over 100,000’ of MaxCell was installed. Three packs of 3” 3-cell MaxCell Plenum was placed throughout the entire tunnel in four of the available nine conduits. MaxCell Plenum was used because the pathways needed to be low smoke zero halogen, chosen because LSZH is a typical requirement for cables and pathways in a tunnel setting. 2,500# pull tape was used in the installation. By putting in 9 pathways, MaxCell saved money by maximizing available sections without incurring additional construction costs. Because MaxCell solutions can be quickly and efficiently installed, it allowed for a higher production rate (footage installed per shift) which resulted in a significant labor savings compared to a traditional HDPE installation.

This project was a challenging job that pushed the limits of distance but proved that MaxCell is a versatile solution for the complex problems faced by today’s engineers, contractors, and network providers.

Want more information on the benefits of using MaxCell in your next tunnel project? Download the case study below or use the web form on this page to contact a MaxCell team member.

DOWNLOAD MORE INFORMATION