OPPORTUNITY

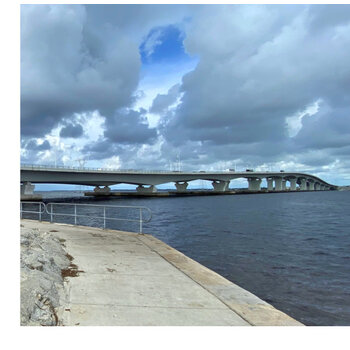

A bridge under construction in Panama City, FL, required a cabling installation along the entire 6,000-foot span of its interior tunnel. This bridge’s primary use was for vehicular traffic, but its piers were tall enough for boats to travel underneath as well.

Between two large maintenance holes, there were four existing fiberglass conduits within the interior on an intermediate hangar drilled and anchored into the concrete with designation for a regional CATV, a telephone company, an alternate access company and the City of Panama City.

There was only one access point for material at the middle of the bridge, which was not open yet, meaning that no machines other than work vehicles were allowed on and material would have to be carried to the access point.

Typically, pulls occur on a bridge’s exterior, but this bridge had a tunnel that measured about 4.5 feet tall that would house the conduits. Additionally, the bridge had eight 45° bends, one bend around each pier that held up a section of the bridge.

SOLUTION

The project contractor suggested MaxCell for the job, with boxes set up at every 1,200 feet. A pulling wheel was anchored on one side of the bridge, pulling no more than 500 pounds at a time, but the pull tape was strong enough to pull the entire length of the bridge instead of only to its halfway point. In two of the conduits, a cable was pulled with a piggybacked 4” 3-cell and an additional pull tape for future use. To preserve space for future bandwidth, the third conduit had an empty 4” 3-cell MaxCell placed at the same time.

The pull length on this installation was challenging because it was a continuous vault-to-vault run, compared to a standard 1,000-1,500 foot bridge pull. Only one box was needed at the middle of the bridge. With the simplicity and ease of installing MaxCell’s flexible fabric innerduct, the contractor was able to complete the installation in half of a day, thus resulting in major time and cost savings.

The pipe that was the closest to the wall of the bridge had to be broken eight times so that the innerduct could be installed throughout the length of the pipe. This installation took the remainder of the week, and the construction manager for the job, who saw both installations, voiced a strong preference for using MaxCell on this and similar jobs.

DOWNLOAD MORE INFORMATION

VIEW PRODUCTS